Revolutionizing Footwear: Advanced Supercritical Foaming Technology

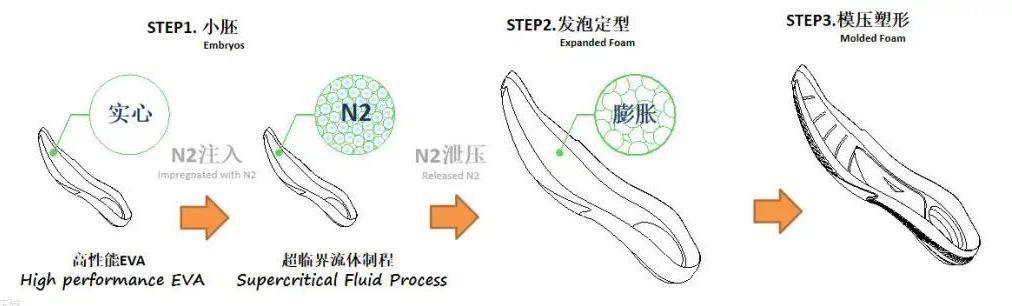

At Kick Ground, we’re proud to announce the launch of our state-of-the-art Supercritical Foaming Sole Production Facility, equipped with fully automated, intelligent, and standardized production lines. Leveraging cutting-edge supercritical fluid foaming (SCF) technology, we specialize in developing lightweight, durable, and sustainable soles using EVA, TPE, TPU, TPEE, and PEBA materials—setting a new benchmark for eco-conscious footwear manufacturing.

Our soles cater to diverse needs:

Athletic Footwear: PEBA-based midsoles for running shoes (70–80% rebound).

Fashion & Casual Wear: Lightweight TPU/TPEE designs with premium aesthetics.

Industrial Safety Shoes: Reinforced EVA/TPU composites for impact resistance.

Why Choose Our Supercritical Foam Sole Technology?

1. Unmatched Material Performance

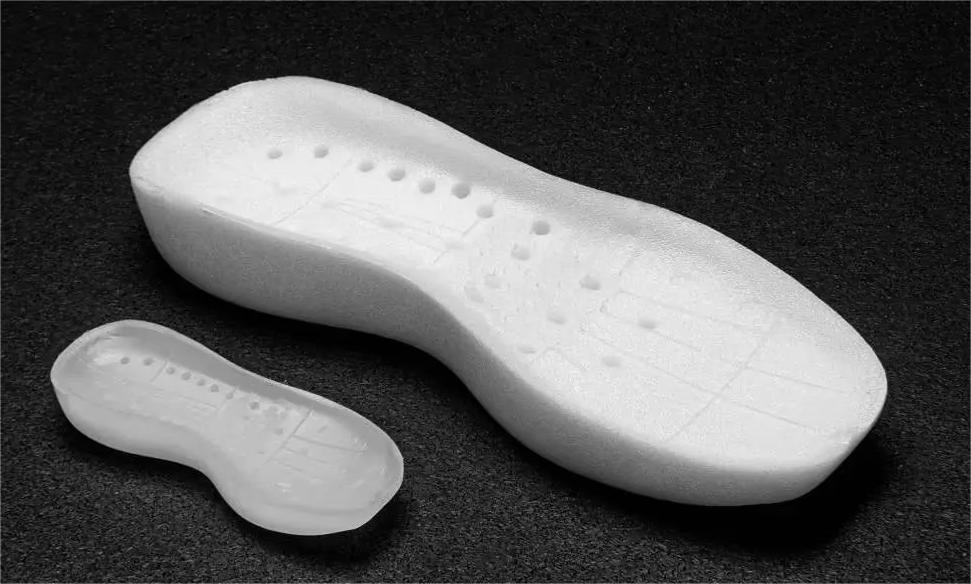

Ultra-Lightweight Design: Achieve densities as low as 0.05–0.08 g/cm³, reducing shoe weight by up to 30% compared to traditional methods.

Superior Elasticity: Boasting a rebound rate of ≥80%, our soles deliver exceptional energy return for enhanced comfort and athletic performance.

Durability: Engineered for high tear resistance and long-term stability, even under extreme conditions.

2. Eco-Friendly Innovation

Zero Chemical Foaming Agents: Utilizing CO₂/N₂ physical foaming, our process eliminates toxic byproducts like azodicarbonamide, ensuring non-toxic production.

Recyclable Materials: TPU, PEBA, and TPEE are fully recyclable, aligning with global circular economy goals.

Odor-Free: Unlike chemically crosslinked foams, SCF technology produces no residual odors.

3. Smart, Sustainable Production

Automated Precision: AI-driven systems optimize foaming parameters (pressure, temperature) for consistent quality and minimal waste.

Energy Efficiency: Reduced thermal processing cuts energy consumption by 25% vs. conventional methods.